You will

need the following tools:

2 x Size 11

spanners.

A Case Gauge

or your gun’s barrel.

A fired case

with the old primer intact.

A few clean

cases.

Let’s first

look at how the system works.

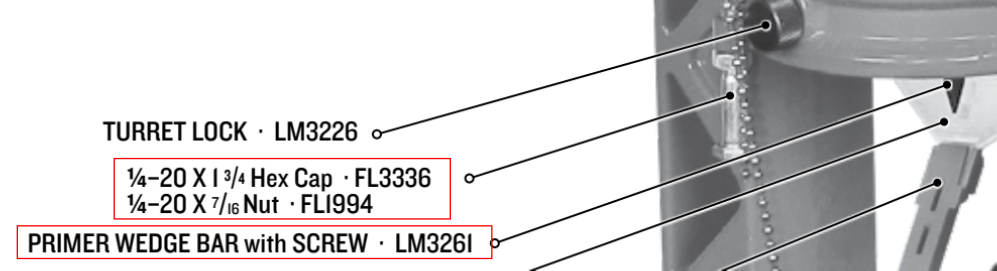

The LM

primes at the top of the stroke unlike the Pro1000 that primes at the bottom of

the stroke. With the LM you can also set your priming depth and this is where

problems happen.

Priming

happens in 2 parts on the LM. Let’s call it Part1 and Part2…

Part1.

The LM uses

a Primer Rocker Arm (LM3239) to raise the primer pin to seat a primer. The

rocker arm is activated by the bolt on the left side of the turret. This is

called the Primer Actuating Bolt (FL3336).

As you raise

the carrier the rocker is forced down by this bolt and raises the primer pin in

station 2 to seat the primer at the top of the stroke. The primer spring that

fits in the primer pin helps the pin retreat as you lower the carrier.

Part2.

Now your

primers are fed through a primer trough on the other side of the press in

station 2. The Lee primer trough’s all work with gravity…the weight of the

primers in the trough feeds the primer on the primer pin.

Using

gravity to feed primers is the easy way to do things…but what if there is no

case to be primed? You don’t want primers all over the shell plate.

The LM

Primer Trough has a little plastic arm on top of the trough. This stops primers

from being fed when there is no case in station 2.

See pic

below, the black part.

Note this

pic is an old large primer trough and I am using it only to illustrate the

parts easily for you. Latest versions should be all black parts for small

primers and red and white for large primers.

This arm is

activated by a case as it rotates from station 1 to station 2, the case moves

the arm back and that collects a primer into the feeding area of the trough.

This happens

at the bottom of the stroke.

As you raise

the carrier to the top, the Primer Wedge Bar (LM3261) on the right side of the

press pushes the black part of the primer trough over the primer pin to place the

primer on the pin.

The primer

is then seated at the top of the stroke.

Now problems

happen when Part1 and Part2 do not work in sync.

If the

rocker raises the primer pin before the primer trough has placed the primer you

will have flipped primers.

If the

primer wedge bar moves the primer onto the pin before it has raised to the top

you will have crushed primers.

If the

primer pin does not raise all the way to the top you will have primers not

seated fully.

It’s all

about timing.

Now let’s

set your priming system to precision.

Now to do

this properly you will have to reset your Dies. The setting of the Sizing Die

plays a critical role here and once you change that setting you need to adjust

the rest of your Dies.

Remove your

turret from the press.

Remove your

shell plate and inspect your primer trough and pin. Make sure it is clean and

that the inside of the carrier where the trough fits is clean, there must be no

dust, debris or oil here.

Check that

your primer pin spring is straight and in good order.

Replace your

primer system and ensure it is aligned as below.

Replace your

shell plate, index rod etc.

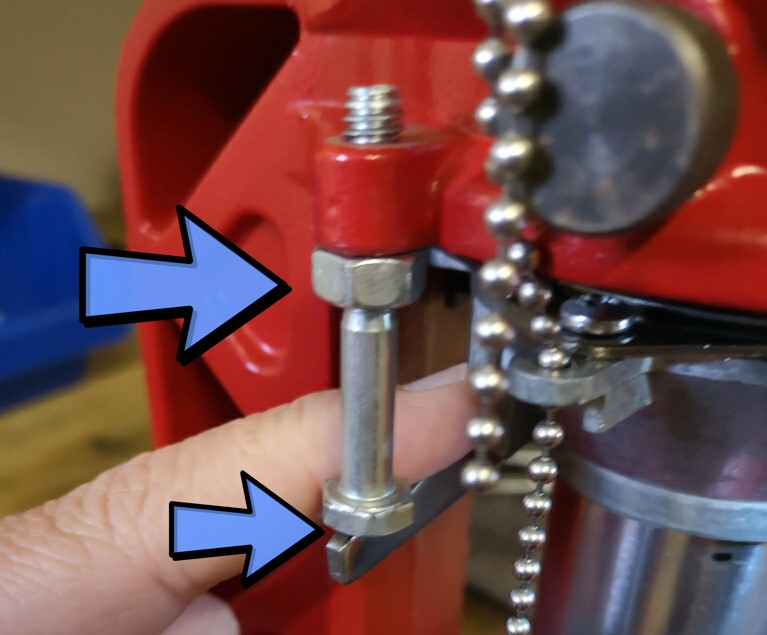

Now look at the primer wedge bar, make sure that is aligned to push the black arm of the primer trough fully in at the top of the stroke. Also make sure that there is no play on the Primer Wedge Bar.

Now let’s

focus on the Primer Actuating Bolt.

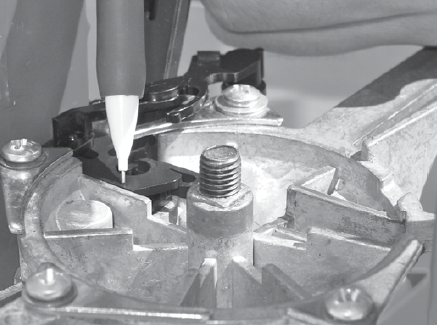

Grab your 11

spanners.

Loosen the

nut (FL1994) and turn it down on the bolt as far as it can go.

Now turn the

bolt up as far as it can go.

Insert the

fired case with the old primer in and cycle it to station 2.

Raise the carrier to the top making sure that your press handle is fully engaging the stop. See pic below. That stop must touch the linkage.

We will

refer to this as the Handle Linkage Stop.

Now turn the

primer actuating bolt down until it makes firm contact with the rocker – there

should be no play in the rocker.

Lower the

carrier and turn the primer actuating bolt down only 2 sides of the nut (The

nut has 6 sides)

Tighten the

primer actuating bolt and make sure there is no play on it – very important.

Use 2x 11

spanners here. One to hold the bolt in position and the other to tighten the

nut to the top. Make sure you do not move the bolt while doing this.

Now if you

raise the carrier to the top you will find that without a case in station 2

there should be a bit of play in the rocker.

With a case

in station 2 there should be no play.

Now refit

your turret and let’s set that Sizing Die.

Your Sizing

Die is set in either in station 1 with the decap pin installed for the 3 Die

setup or in station 2 –without the decap pin for a 5 Die setup.

Raise the

carrier to the top of the stroke.

Start

turning the die into the turret. Turn the die until it makes firm contact with

the carrier, make sure that the stop on the Handle Linkage is engaged.

Grab your

Case Gauge or the barrel of your gun….obviously removed from the gun in a safe

manner.

Size a case

and check if it has sized all the way. Again make sure that the Stop on the Handle

Linkage is engaged.

Take the

case and see if it fits in the Case Gauge or your Barrel, it must be flush and

fall easily in and out of the Gauge/Barrel.

If not turn

the die in in small increments and test until your case is perfectly sized – Do not turn the Die in more than ¼ from

touching the shell plate.

Now check

the Stop on the Handle Linkage, make sure that with the carrier at the top of

the stroke while sizing a case that there is not too big of a gap between the

handle and the stop.

A millimetre

gap is ok.

If you set

your Sizing Die too deep you will find that your primers are not seated flush.

You will then attempt to fix this by turning the Primer Actuating Bolt deeper

and this is where problems start.

If you set

your Sizing Die or any other Die too deep you remove the initial setting of the

Primer Actuating Bolt.

If the

Primer Actuating Bolt is set too deep you will have priming issues as described

above but more importantly you are now placing too much pressure on the carrier

and you will crack your carrier.

Now grab

those clean cases. Fill your Primer Tray and load them into the Primer Trough.

Make sure that the Black Arm on the Primer Trough is in the correct position.

Size and

deprime your cases in station 1 or station 1 and 2 if you are running a 5 Die

Setup. In station 2 at the top of the stroke your cases will be primed.

Open the

Case Retainer at station 3 to remove your primed cases.

Inspect the

primed cases looking for high primers.

If you do

find high primers you can adjust the Primer Actuating Bolt deeper.

BUT make sure you have

eliminated any other issues that could cause high primers.

Have you

ensured that you have raised the carrier to the top of the stroke?

Was the

sizing difficult? Add some lube to assist in sizing.

Are your

primer pockets in good order?

If you have

eliminated the above then only set your Primer Actuating Bolt deeper.

BUT only do this in small

increments and testing after each setting. Remember if you set the Primer

Actuating Bolt too deep you will run into issues.

And a small

change in the Primer Actuating Bolt makes a big change at the Primer Pin end.

If you

follow these steps and learn how the priming system on the Load Master works,

you will find that priming on the Load Master is not an issue and is very easy

to sort.

Priming on

the Load Master is precise…