These posts

will be to try and help you learn about the reloading process. I have found

that some new reloaders struggle in the beginning because they do not

understand the whole process. By this I mean understanding what each die does

and why…so let’s jump in.

Warning –

this will only apply to 9mmp loads as it is by far the most reloaded cartridge

in SA. Loads discussed are my own. Do not copy them, do a proper safe load

development.

Part1 – Resizing

So you have

shot a few rounds at the range and hopefully you remembered to collect your

cases; they are the most expensive part of the reloading components after all.

The only

cases I would suggest you leave in the trash can is Berdan primed cases but

more on that later.

Let’s look

at what happened to the case when it was fired and why we need to resize. For

that we need to look at the design of the 9mmp.

9mmp, 9mm

Para, 9mm Luger, 9x19 are a few of the names associated to the 9x19mm

Parabellum, designed by Georg Luger in 1902 for the Luger Semi Auto Pistol. You

see why it is sometimes called 9mm Luger – actually it is officially designated

as the 9mm Luger by the Sporting Arms and Ammunition Manufacturers' Institute

(SAAMI).

Here in good

old South Africa is more commonly referred to as 9mm Para – Para being for Para

bellum – taken for the Latin “Si vis pacem, para bellum”. Different names for

the same thing…just don’t confuse it with 9mm Makarov or 9mm Short.

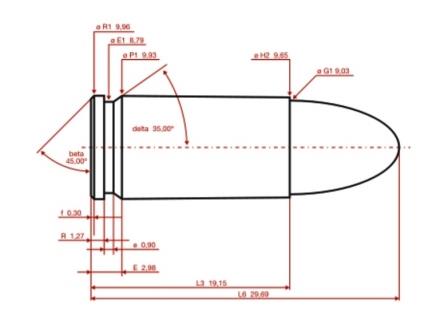

The 9mmp is

a rimless, tapered case.

What is

rimless? Just what it says a 9mmp does not have a rim as such. Most revolver

cases have rims that hold the case in place in the cylinder. A 9mmp has an

extractor groove and a “rim” to aid extraction. This “rim” however does not

hold the cartridge in the chamber as a Rimmed Revolver case holds the cartridge

in a revolver cylinder.

Tapered?

This is an important part to understand. Simply the bottom of the case before

the extractor groove is bigger than the case mouth. Not by much, only 0.28mm.

This is the part of the design that could make resizing difficult.

The 9mmp or

most other semi auto pistol calibres headspaces on the mouth of the case; take

your barrel out of your gun safely, look down the chamber and you will note a

ridge just before the rifling of the barrel. The case stops on this ridge when

loaded in the chamber.

Now when the

cartridge is loaded from the magazine it will stop on this ridge in the chamber.

When the primer pin/striker hits the primer, the primer is crushed and ignites

the gun powder in the case. The gun

powder creates a pressurized gas that expands the case to seal the breach of

the firearm. This seal of the chamber is to prevent gases from escaping

rearwards and force the bullet down the barrel on to the target.

Cases are

made of brass and expand under pressure to form a closed gas tight fit with the

sides of the chamber, and then contract slightly so that the case remains loose

and can be removed by the extractor.

Now if you

understand this you will see that the case takes a lot of pressure and has now

lost its original shape. Now we need to reshape the case back to its original

dimensions to reload it again.

Ps. you need

to clean your brass before you continue; there are many ways and we will

discuss this later but for now let’s imagine the case has been cleaned.

So now we get to part 1 of reloading a 9mmp, resizing it back in shape; this is done with a resizing die, this die also removes the old primer.

Let’s look

at the Lee resizing and decapping die…and in my mind you cannot get a better

die for the job. This die has a carbide sizing ring that resizes the case. You

do not need to lube cases for resizing when using a carbide die BUT lubing the

cases will just make life easier. And on a progressive make things run smooth

and help in extending the life of the carrier.

Setting up

this die is where most problems begin. An incorrectly set die will not fully

resize the case which will lead to feeding problems. Follow Lee’s instructions.

This applies to any press you set this up in; be it a single stage or

progressive.

·

Set the lock ring as far up on the die as it

will go.

·

Make sure you have the correct shell holder

installed if you are using a single stage or turret press, same goes for a

progressive press - use the correct shell plate. Raise the ram/carrier to the

top of the stroke. Keep pressure on the ram/carrier.

·

Turn the die in until it makes firm contact with

the ram/carrier.

·

Drop the ram/carrier slightly and turn the die ¼

more in. (LOAD MASTER NOTE! Only turn the die in more until your case is

successfully sized, do not turn the die in more than ¼. Doing this will lead to

priming issues – See our Load Master priming article in our blog.)

·

Raise the ram/carrier again and keep pressure,

turn the lock ring down and finger tighten.

Your sizing

die is now set.

The decapper

should be set deep enough to remove the primer but not so deep as to obstruct

the case from fully entering the die. You can set the decapper clamp so that if

you get a Berdan primed case in your press it just pushes the decapper out

instead of breaking it. But more importantly you should learn to feel what is

happening with the press. If you feel resistance here rather stop and have a

look.

Some

European spec 9mmp cases (S&B NX as example) are found here these days.

These have a smaller flash hole and can damage decapping pins. Replacing your

pistol decapper with a rifle or Universal decapping pin helps but keep spares

on hand for these cases…and again do not force the press.

Ok, now run

a few cases through the resizing die. Have a look each time to make sure the

bottom of the case is going all the way in the die – not the extractor groove.

The die is

designed to resize the case back to its tapered original size which is why

sometimes a 9mmp can be hard to resize but following these instructions, adding

a bit of lube and not short stroking the press should give you properly resized

cases every time.

However

cases do not last forever. You could get cases where the bottom has “bulged”

from numerous firings or high pressure loads. These cannot be resized with the

normal sizing die. The only way to correct them is to either roll them on a

roll sizer or run them through a Lee Bulge Buster.

Now there

are 2 ways of checking that your cases are properly sized. You could either

barrel drop them in your guns barrel – removed from the gun! Or a much better

way is to buy yourself a Case Gauge…these are designed to SAAMI minimum specs

and if the empty case fits in all the way and falls out easy, it will fit in

any 9mmp gun.

Up next we

look at priming…