This article

focuses on 9mmP Bulge Busting.

This bulge

busting story is going to drive me crazy.

There’s more

myths than facts out there. Most reloaders do not need to Bulge Bust.

This bulge at

the bottom of the case is usually caused by high pressure loads or loose

chambers. Some handguns have a looser chamber to assist in the feeding of ammo.

Sport

Shooters with 9mmP Major Open Guns running major ammo will usually find their

cases have bulged after firing due to the higher pressures they are running.

Glocks do not automatically cause

bulges.

A modern

Glock’s chamber has no more an unsupported chamber than any other modern

handgun.

Old Glock 22’s

had a problem but newer models have fixed the issue.

There are 2

methods to fix this.

A Roll

Sizer, which is an expensive bit of kit.

Or one of

the Lee Precision Bulge Buster kits.

The Lee method

of fixing a bulge is to use either of their Bulge Buster Kits with a Factory

Crimp Die.

You do this

by removing the crimp sleeve from the Factory Crimp Die and forcing the case all

the way through the Factory Crimp Die. The case needs to go all the way through

the Die body so that the bulge at the bottom of the case can be forced out with

the carbide ring inside the Factory Crimp Die.

Lee does not

list a Bulge Buster for 9mmP but reloaders have figured out to use the 9mm

Makarov Factory Crimp Die.

Why use a

9mm Makarov Factory Crimp Die?

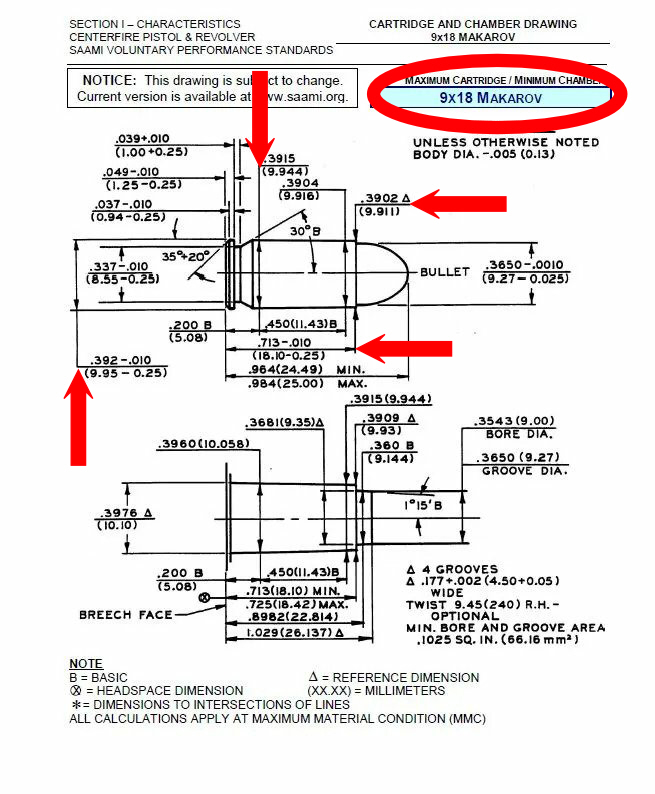

The base of

the 9mmP case and a 9mm Makarov case is almost the same.

9mm Makarov

has a base of .3915inch, 9mmP has a base of .3910inch…this tiny difference is

what allows you to use the 9mm Makarov Factory Crimp Die to bulge 9mmP cases.

But 9mm

Makarov is not in any other way the same as 9mmP and the important difference

are:

9mm Makarov

is shorter by 1.05mm.

9mm Makarov

has a case mouth of 0.3902inch.

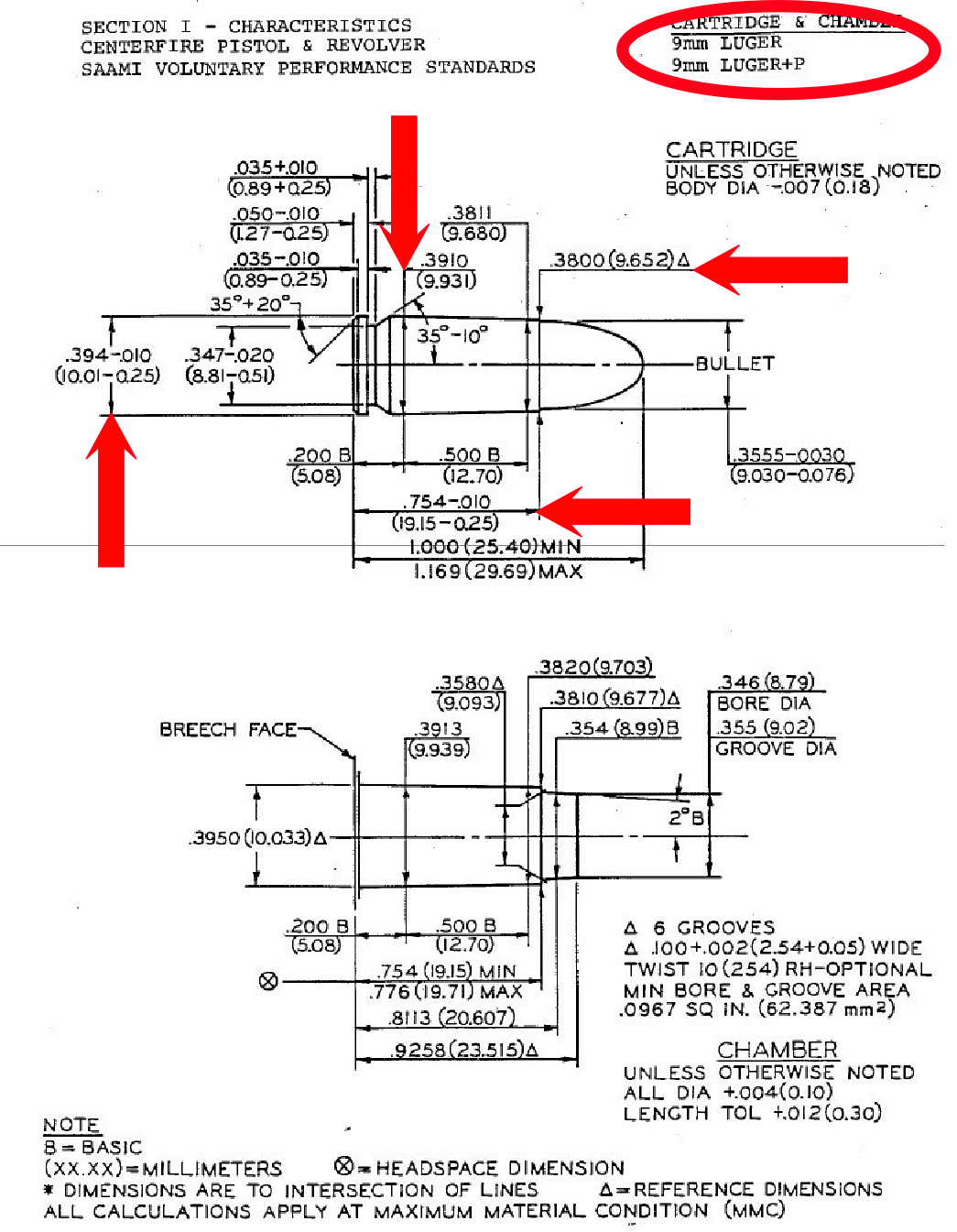

9mmP has a

case mouth of 0.3800inch.

9mmP is a

tapered case, the bottom is bigger than the top.

9mm Makarov is

a straight walled case, the bottom and the top is basically the same size.

Again this is one of the reasons why you use this Factory Crimp Die to bulge

bust 9mmP.

And the

tapered case of the 9mmP is why you cannot use a 9mmP Factory Crimp Die to

bulge bust.

And no you

cannot use a 9mm Makarov Factory Crimp Die to crimp 9mmP.

It will not

give a sufficient or correct TAPER crimp because of the difference in case

design.

And yes 9mmP

is to be TAPER crimped not ROLL crimped. Your ideal crimp should prevent any

type of bullet setback and your case mouth should measure 0.3800 inch after you

have applied your crimp.

So your ammo is not feeding correctly in

your handgun. The slide does not close all the way…you might have a bulged case

problem.

Now before

you run off to buy a Bulge Buster check this first.

Is your

sizing die correctly installed and are you completing the stroke? Size a case

and barrel drop or case gauge it. If it drops or gauges correctly, your case is

not the issue and you do not have a bulge problem. (To barrel drop, remove the

barrel from your gun)

Now check if

your Cartridge Overall Length is not the problem…which with the new coated

bullets on the market these days, is usually the problem.

Load a dummy

round, no powder or primer. Drop it in your barrel.

Did it plunk

in? Does it sit flush? Can it spin freely in the chamber?

If not you

need to lower your Cartridge Overall Length slowly until the rounds fits in

your chamber. Coated bullets can have a bigger ogive (the shape of the bullet)

and you need to load them shorter than a CMJ.

If this is

the case, you need to lower your COL. Do this bit by bit until the round fits

but take note not to compress the powder charge!

Did you flare your case sufficiently to allow the bullet to seat? If you do not add enough flare you could buckle the case while seating the bullet. This will also cause feeding issues.

Lee Precision has solved this by adding a step on their expanders, this will step the case so that you can seat the bullet straight while not flaring too much.

Now if you

have eliminated the above you have a bulged case.

Again, there

are 2 ways to address this issue.

Roll Sizing

which is probably the best way but is a very expensive solution or the Lee

Precision Bulge Buster.

Lee

Precision has 2 models, one for use on a Single Stage Press or a model for

their excellent APP Press. The APP option is by far the quickest way to Bulge

Bust.

I hope this read

will bust the myth of the bulge.

Great blog post! Summed everything up a layman can understand in plain, simple English.

This die does the calibration.

https://www.youtube.com/watch?v=isq2gwDiJTk&t=118s